Applications:

Cutlery: knives, kitchen utensils, Industrial equipment: pumps, valves, shafts, bearings, automotive parts, Marine hardware (less severe conditions),Medical instruments, Military components

Cutlery Industry: Knives, kitchen utensils

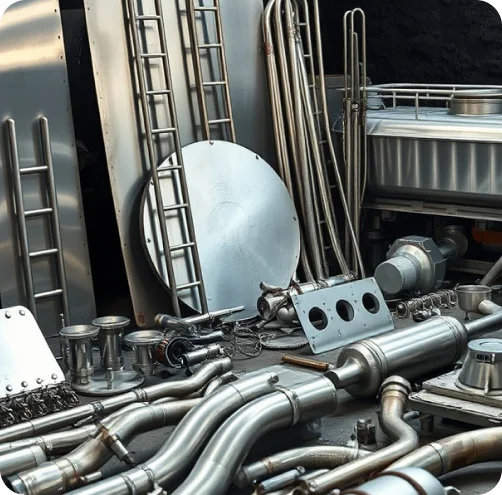

Industrial Equipment: Pumps, valves, shafts, bearings

Automotive: Exhaust systems, engine components

Tools & Hardware: Hand tools, fasteners

Aerospace/Military: Aircraft parts, gas turbine blades,Certain armament components.

Medical: Surgical instruments and dental tools

Applications:

Cutlery: blades, knives, scissors, Medical: scalpels, dental, surgical tools. Industrial: needle valves, shear blades, bushings, Hand tools: springs, screwdrivers, wire, Pump/valve parts: hard, corrosion resistant, Fasteners, pins: stress, mild corrosion, Auto/Aero: fasteners, minor parts.

Cutlery: Knives , scissors due to excellent hardness and edge retention

Surgical and dental instruments: Wear resistance and moderate corrosion resistance

Shear blades and hand tools: High strength and durabilit

Needle valves and pump parts: Mechanical robustness

Machine components: Gears, shafts, and fasteners

Industrial equipment: Mild corrosive environments