Applications:

Chemical processing, oil and gas exploration, marine environments, water and wastewater treatment, heat exchangers, pressure vessels, and structural components due to its high strength and excellent corrosion resistance.

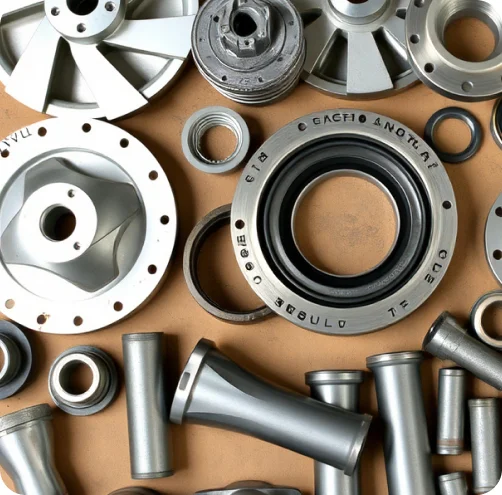

Offshore oil and gas industry: Pipework systems, risers, manifolds

Chemical processing: Pipelines, pressure vessels, heat exchangers

Marine engineering: Shipbuilding, desalination plants

Construction: Architectural cladding, structural components

Aerospace industry components: Aircraft engines and landing gear, due to its excellent strength-to-weight ratio and fatigue resistance

Pharmaceutical and geothermal equipment: Benefiting from its strong corrosion resistance and durability in harsh chemical environments.

Oil & Gas: Offshore platforms, risers, pipelines, pressure vessels, valves

Chemical processing: Reactors, heat exchangers, storage tanks, piping systems

Marine engineering: Shipbuilding components, seawater handling systems, propellers, shafts

Power Generation: Flue gas desulfurization units, boilers, cooling systems

Pulp & Paper: Bleaching equipment, chemical processing vessels

Pharmaceutical: Process equipment requiring corrosion resistance and hygiene standards