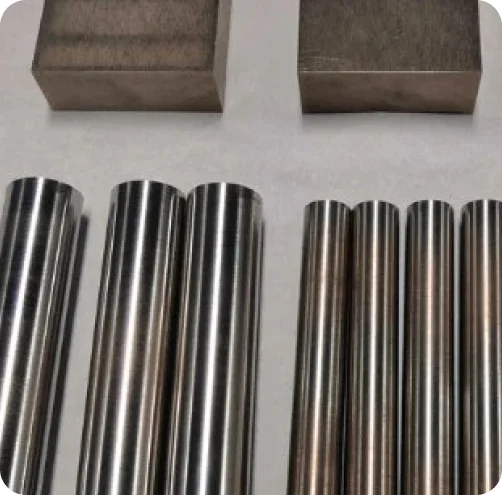

Pure metals like chromium (melting point 1907°C) form passive oxide layers essential for stainless steel corrosion resistance, while nickel (1455°C) stabilizes the austenite phase in grades like 304/316 for non-magnetic ductility, and molybdenum (2623°C) enhances pitting and crevice resistance in duplex steels such as 2205. Titanium (1668°C) prevents carbide precipitation and sensitization in ferritic/duplex alloys, cobalt (1495°C) provides high-temperature stability and wear resistance in superalloys for turbines, and tungsten (3422°C) imparts extreme hardness and red-hardness to high-speed tool steels—yet alloying these with iron in stainless formulations optimizes strength, cost, and recyclability for industrial applications

Applications:

Stainless steel production—nickel improves corrosion resistance and toughness, Nickel alloys (ni chrome, Monel, Inconel) for heating elements, marine, chemical, and high-temperature applications, Rechargeable batteries (NiCd, NiMH), coinage, and catalysts.

Metallurgy & Alloy Production: Stainless Steel, High Performance Alloys Production

Chemical Processing: Chemical reactors, storage tanks, and piping requiring high resistance to acids, alkalis, and chlorine, catalysts in hydrogenation and organic synthesis processes

Electronics & Energy: Rechargeable batteries (Ni-Cd, Ni-MH) and fuel cells for mobile devices, power tools, and electric vehicles, electronic connectors and components requiring reliable conductivity and corrosion resistance

Aerospace & Power Generation: Jet engine components, rocket motors, and turbine discs exposed to extreme heat and stress, nuclear power plant parts needing outstanding durability at elevated temperatures

Automotive: Spark plug electrodes and exhaust system components exposed to corrosive gases and high temperatures

Coinage & Consumer Goods: Coins and medals for their durability and resistance to wear, Kitchenware, tools, and medical devices demanding non-reactivity and longevity

Metallurgy & Steelmaking: Alloying element in stainless steel and high-strength steels to improve hardness, toughness, corrosion resistance, and high-temperature strength

Chemical Industry: Used in catalysts for petroleum refining, organic chemical production, and as pigments and solid lubricants

Aerospace & Defense: Components in jet engines, missile parts, and heat-resistant alloys requiring excellent thermal stability

Electronics & Electrical: Filaments, electronic contacts, and components in lighting and power devices due to high conductivity and thermal resistance

Energy & Power Generation: Parts for nuclear reactors, high-temperature furnace components, and thermal power plants

Construction & Industrial: Solid lubricants, pigments, and corrosion inhibitors in cooling and heating systems

Chemical Processing: Tanks, piping, reactors, and equipment handling corrosive chemicals

Petrochemical & Oil & Gas: Refinery components, pipelines, and gas plants operating under high temperatures

Power Generation: Boiler tubes, superheater and reheater tubing, flue gas handling systems, and gas turbine parts

Furnaces & Heat Treatment: Furnace tubes, muffles, burner components, annealing covers, and kiln linings

Marine: Components exposed to high temperatures and corrosive seawater environments

Aerospace & Automotive: Shaft, fasteners, and parts requiring heat resistance and mechanical strength

Aerospace: Used in aircraft engines, airframes, compressor blades, landing gear, and exhaust systems due to its high strength-to-weight ratio and corrosion resistance

Medical: Preferred material for surgical instruments, implants, dental devices, and prosthetics because of its biocompatibility and durability.

Chemical Processing: Used in reactors, heat exchangers, piping systems, and vessels handling aggressive chemicals due to its excellent corrosion resistance

Automotive & Sports: Used in race cars, motorcycles, bicycle frames, sports equipment, and lightweight automotive parts for strength and weight reduction.

Industrial & Power Generation: Found in turbine blades, condenser tubes, and heat exchangers in power plants, improving efficiency and service life.

Consumer Products & Architecture: Titanium is used in eyewear, watches, jewelry, and architectural elements for its durability and corrosion resistance.

Applications:

Cobalt is widely used in high-performance superalloys for jet engines, gas turbines, and power generation equipment due to its strength and heat resistance. It is a key component in permanent magnets (such as Alnico), rechargeable lithium-ion batteries, and catalysts in petroleum refining and chemical synthesis. Additionally, cobalt is used in ceramics and glass for blue pigments, as well as in cutting tools and wear-resistant alloys where durability and hardness are essential.

Battery Technology: Critical for lithium-ion battery cathodes, powering smartphones, electric vehicles, and energy storage systems with improved performance and longevity

Aerospace & Superalloys: Used in high-temperature-resistant superalloys for jet engines, gas turbines, and power generation, offering strength and thermal fatigue resistance

Medical & Dental: Cobalt-chromium alloys are widely used for prosthetics, dental crowns, and implants due to their biocompatibility and wear resistance

Permanent Magnets: Essential in manufacturing strong magnets like samarium-cobalt, used in electric motors, wind turbines, and audio devices.

Cutting Tools & Hard Alloys: Added to tool steels and cemented carbides for enhanced hardness, wear resistance, and durability in machining and mining industries

Catalysts & Chemical Industry: Used as a catalyst in petroleum refining and chemical processing to reduce emissions and improve efficiency

Applications:

Tungsten is predominantly used in manufacturing cutting tools, drill bits, and wear-resistant carbide inserts essential for mining, metalworking, and construction industries due to its extreme hardness and durability. It is also vital in aerospace for high-temperature engine components, in electronics for filaments and electrical contacts, and in medical fields for radiation shielding and surgical instruments

Metalworking & Mining: Widely used in tungsten carbide cutting tools, drill bits, and wear-resistant parts for enhanced durability and hardness in mining, construction, and metal fabrication

Energy & Industrial: Tungsten alloys are used in welding electrodes, nuclear reactors, wind turbines, and heavy machinery requiring strength and stability at extreme conditions.

Electronics: Essential in electrical contacts, filaments for light bulbs, semiconductors, and electron emitters, sustaining performance at high temperatures

Automotive: Incorporated in engine parts, turbochargers, and brake systems where wear resistance and thermal stability are needed.

Medical: Applied in surgical instruments, radiation shielding, and implants due to its biocompatibility and strength

Jewelry & Fashion: Used in scratch-resistant rings, watches, and accessories known for lasting finish and wear resistance